Our Services

Sectors and Skills

CHEMICAL & PETROLCHEMICAL

petrochemical plants – water treatment plants

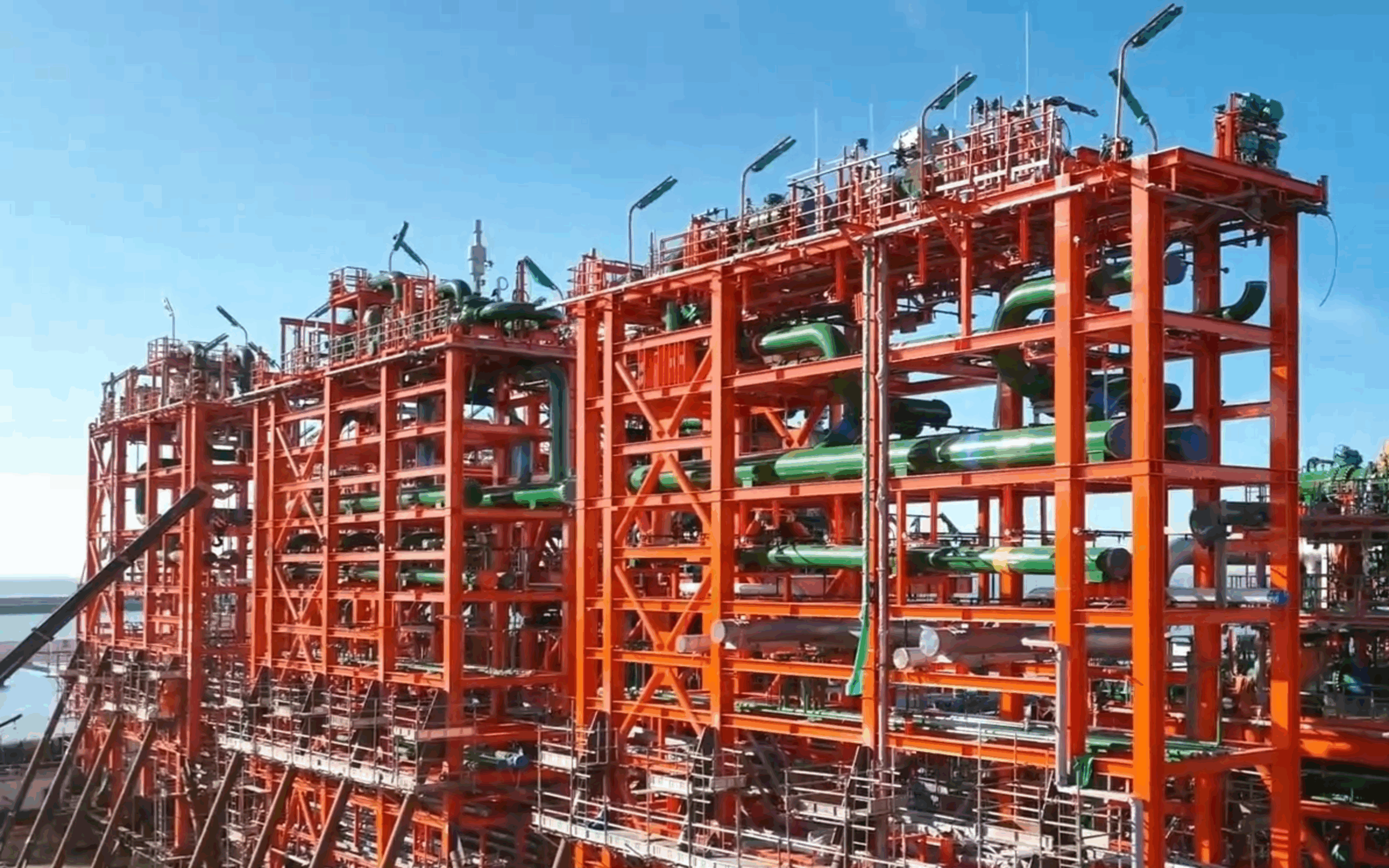

OIL & GAS

on-shore and off-shore Oil&Gas plants

POWER PLANT

Open cycle and combined cycle thermoelectric power plants - Nuclear plants

RENEWABLE ENERGIES

Wind power plants – photovoltaic plants – hydroelectric power plants – Storage plants

BUILDINGS

Industrial plants of all types

Project Phases

FEED ENGINEERING

BASIC DESIGN

DETAIL DESIGN

COSTRUCTION DESIGN AND MANAGEMENT

FIELD ENGINEERING

PRECOMMISSIONING – COMMISSIONING AND START UP

Piping and Stress Analysis Engineering

Since 1987, the consortium member PROGETTO 10 S.c.a.r.l. has been offering engineering services in the industrial sectors, accumulating considerable experience in the design of:

Conventional Thermoelectric Plants (Coal and Fuel Oil)

Combined Cycle Plants

Renewable Energy Plants

Nuclear Plants

Oil&Gas Plants (on-shore / off-shore)

Main activities developed:

P&ID mechanization

Line list

Piping Classes

General Layout

Material Take-Off (M.T.O)

Detailed Layout

Study of structures and Pipe Rack

Input per le Opere Civili

Modellazione in 3D

(Piping-Strutture -Apparecchiature)

Nozzle Orientation and Equipment Follow-up

Cad Administrator

Stress Analysis Calculations and Calculation reports

Itemized Support Data Sheets

Piping Support Design

Model review 30-60-90% and related reports

Piping Plan Extraction (GAD)

Axonometric Extraction and Piping Spool

MR & TBE for Piping and Piping Support”

Machinery And Package Engineering

The Static Equipment/Machinery and Packages department offers engineering services in the design of equipment & packages that find application in petrochemical and gas treatment plants (on-shore/off-shore).

Main activities developed:

Mechanical design of Static Equipment using dedicated calculation software

Preparation of Mechanical Datasheets and technical documentation for offer and order

Material Requisition & Inspection

Datasheets

Supplier Tabulation Activities

Technical support to Customers in evaluating offers

Mechanical support for the preparation of P&IDs

Focal point activities in the exchange of technical documentation between the various technical departments (piping, instrumentation, civil, process)

Follow-up of equipment

Technical coordination of departments in follow-up

Civil And Structural Engineering

The company A2G s.c.a.r.l. is the consortium member, established in 1988, which operates in the civil engineering design sector in support of the most important design and construction companies in Italy and abroad.

To maintain the high quality standards required by the market, A2G has specialized and experienced personnel and adequate and updated hardware and software equipment dedicated to design.

Main activities developed:

Progettazione architettonica di edifici industriali

Progettazione strutturale antisismica di edifici in acciaio e cemento armato

Progettazione di fondazioni superficiali e speciali su pali

Progettazione reti underground

Computi metrici

Electrical Engineering

Electrical and instrumental engineering represents for API a service firmly established thanks to the history of the company member I.T.I. s.r.l. which dedicated itself to these disciplines for over 40 years. Although the structure offers high-level multidisciplinary engineering services, this discipline represents an important cornerstone within the API consortium both for the volumes of activity that it is able to develop and for the high level of specialization of the personnel that ranges across all sectors, with particular reference to the historical experience in high voltage systems, production systems of both renewable and traditional energy, and petrochemical plants. The great experience gained over the years allows us to design High, Medium and Low Voltage systems including the related plant engineering as well as all the instrumental systems necessary for the control and regulation of the plants.

Main activities developed:

Purchase specification;

Project Techinical specification;

Technical Specification for HV, MV and LV equipment;

Data Sheet for HV, MV and LV equipment;

Supplier technical and Economical bid evaluation;

Supplier Negotiations;

Supplier’s Control Quality Documentation;

Supplier’s Follow-Up;

Load Flow and Voltage Drop Analysis;

Short Circuit Analysis;

Motor Starting Analysis;

Relay Protection Study;

Harmonic Analysis;

Power Factor Study;

Earthing Grid Study;

Lighting Calculation;

HV, MV and LV Cable Sizing;

Electrical Substation Sizing;

square size

Power Balances;

One line, Three Line, Measure and Protection Diagram;

HV, MV and LV Equipment Logic Diagram;

Wiring Diagram;

HV Electrical Substation;

MV and LV Eletrical Substation;

Power Systems;

Lighting Systems;

Earthing Grid Systems;

Lightning Discharges;

Material Take Off and Pricing;

Cable List;

Load List;

3D Modelling;

Site Survey;

Factory Acceptance Tests (FAT);

Site Acceptance Tests (SAT);

Expediting;

Commissioning and Start-Up.

Instrumentation and Control Engineering

Any industrial plant, whether simple or complex, is generally served by automation and control systems that allow the relative regulation and command by the operator. Following the functional and operational criteria defined by the process, the consortium member I.T.I. s.r.l. develops such systems in line with the most modern technological standards in compliance with the required safety parameters.

Main activities developed:

Purchase specification;

Technical Specification for Measure, Control and Safety Instruments;

Technical Specification for DCS and ESD Systems;

Data sheet for Measure, Control and Safety Instruments

Supplier technical and Economical bid evaluation;

Supplier Negotiations;

Supplier’s Control Quality Documentation;

Supplier follow-up;

P&ID validation and comments;

Validation and comments on safety and control philosophies;

Instrument classes;

Instrumentation database;

SIL calculations

IS calculations;

Control rooms;

Control and safety system block diagrams;

Instrumentation block diagrams;

Telecom block diagrams;

Architetture dei Sistemi DCS e ESD;

Layout posizionamento strumentazione;

Layout percorsi cavi;

Liste strumenti;

Lista apparecchiature Telecom.;

I/O lists;

Loop connection diagrams;

Junction Box connection diagrams;

Cable lists;

Mechanical/pneumatic/electrical assembly specifications;

Material Take Off and Pricing;

3D plant modeling;

Site Survey;

Factory Acceptance Tests (FAT);

Site Acceptance Tests (SAT);

Expediting;

Commissioning and Start-Up.

Telecommunications Engineering

Main activities developed:

Purchase specification;

Data sheet apparecchiature Telecomunicazioni;

Supplier technical and Economical bid evaluation;

Supplier Negotiations;

Supplier’s Control Quality Documentation;

Supplier follow-up;

Schemi a blocchi Telecomunicazioni;

Architetture Sistemi Telecomunicazioni;

Layout posizionamento PAGA, CCTV e IDS;

Layout percorsi cavi;

Lista apparecchiature Telecomunicazioni;

Cable lists;

Tipici di montaggio;

Material Take Off and Pricing;

3D plant modeling;

Site Survey;

Factory Acceptance Tests (FAT);

Site Acceptance Tests (SAT);

Expediting;

Commissioning e Start-Up impianti.

Fire & Gas Detection

The API consortium develops basic and detailed engineering relating to these systems by having a section dedicated to them.

Main activities developed:

Purchase specification;

Specifiche tecniche sistema FGS;

Data Sheet strumenti F&G;

Supplier technical and Economical bid evaluation;

Supplier Negotiations;

Supplier’s Control Quality Documentation;

Supplier follow-up;

Instrumentation database;

Layout posizionamento strumenti F&G;

Layout percorsi cavi;

Liste strumenti;

I/O lists;

Junction Box connection diagrams;

Cable lists;

Tipici di montaggio;

Material Take Off and Pricing;

3D plant modeling;

Site Survey;

Factory Acceptance Tests (FAT);

Site Acceptance Tests (SAT);

Expediting;

Commissioning and Start-Up.

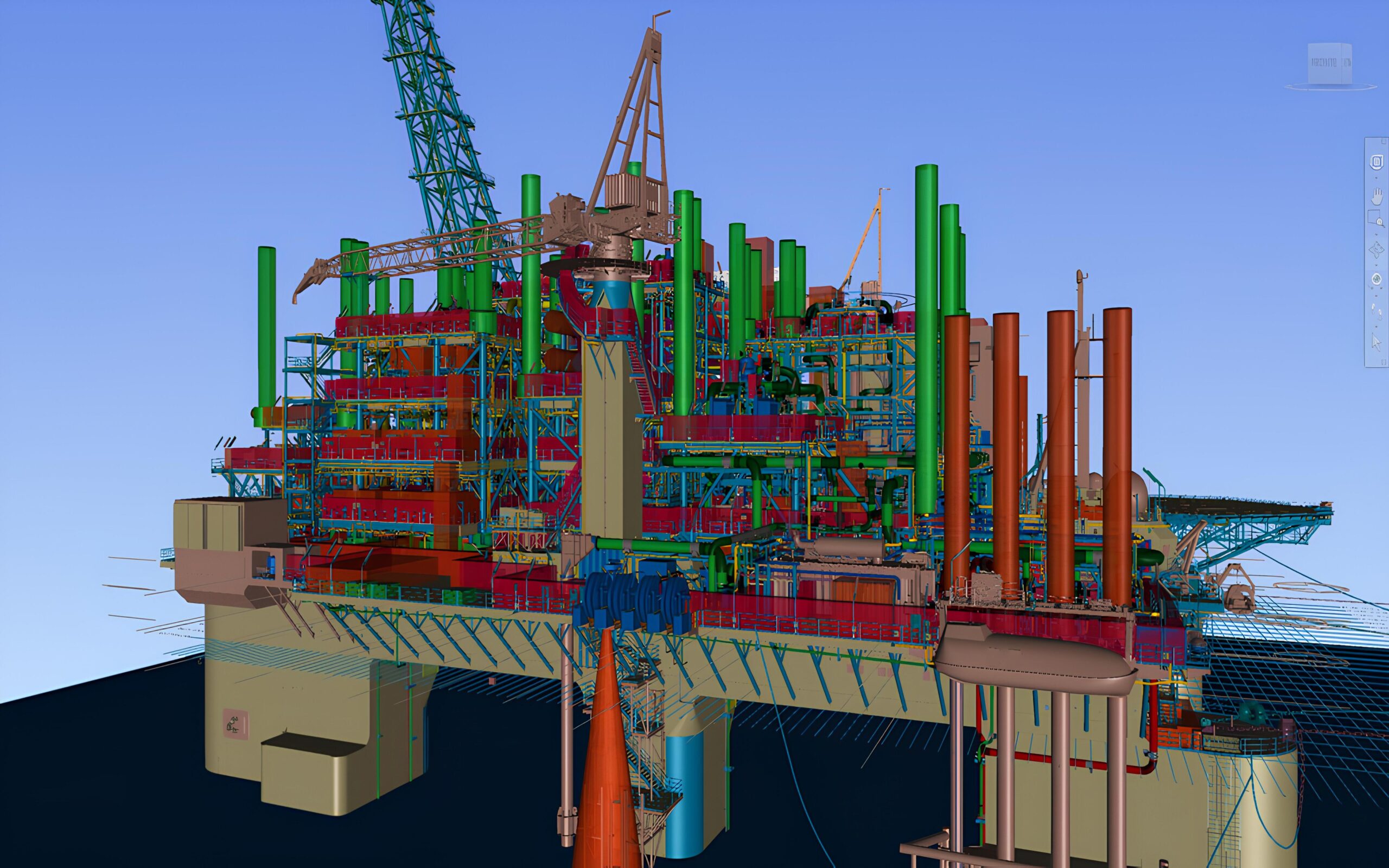

3D Models Administration

We develop projects with high technological content. The activities to be developed are organized by identifying an integrated project team for each specific discipline. Our designers are coordinated by team leaders in order to be able to manage each problem in the most fluid way possible, thus limiting interference between the different systems developed by the individual disciplines.

API uses 3D modeling systems in the development of the engineering of large industrial plants, both to meet the needs of the primary client and to optimize the verification and revision processes in compliance with quality procedures.

3D modeling software used:

Intergraph Smart Plant 3D

Intergraph PDS

Aveva PDMS

Intergraph Cadworx Plant Professional

ESApro Piping 3D

Pro/Engineer 4.0

Microstation V8 XM

Telefono

+39 06/8416187

info@apieng.com

Pec

consorzioapiengineering@legalmail.it